Circular Economy

Working toward a circular materials economy by promoting collaboration to incorporate sustainable practices and materials in the production and content of vehicles.

Suppliers Partnership for the Environment (SP) is working to support automotive industry goals around accelerating the transition to a more circular economy, one where materials are thoughtfully designed, responsibly sourced, reused, and recovered across their lifecycle. Through collaboration among automakers, suppliers, and key partners, SP members are working to identify new opportunities to reduce waste, extend material value, and close resource loops.

SP’s Sustainable Materials Work Group provides a forum for members to collaborate on advancing sustainable material strategies, such as increasing the use of recycled and renewable content, while also exploring downstream circularity opportunities and material content reporting processes.

In parallel, SP’s Sustainable Packaging Work Group works minimize automotive packaging waste and address barriers to packaging recyclability / reuse across automotive operations.

And, SP’s Responsible Battery Work Group provides a forum for automakers and suppliers to work together to advance responsible management of advanced vehicle batteries.

Through these complementary initiatives, SP provides a space for companies to discuss challenges and opportunities in striving toward circularity, identify and pilot practical solutions, and co-develop tools that help to enable meaningful progress toward a more sustainable and circular future.

Featured Resources

Waste Metrics for Automotive Operations

Commons definitions and approaches for measuring and reporting on the management of waste.

Sustainable Packaging Specification Recommendations

Practical recommendations to source sustainable packaging designs for use in automotive manufacturing operations.

Automotive Packaging Materials Collection & Handling Practices

Voluntary guidelines for sorting, storing, transporting, and recovering packaging materials.

EV Battery Safe Handling Guidance

Summarizes available resources, options and considerations related to handling of EV batteries after their removal from a vehicle.

EV Battery Transportation Guidance

Summary of regulations and requirements for stakeholders handling an EV battery at the end of its useful life.

Recycled Content Guidance

Industry-supported definition and straightforward approach for measuring recycled content of automotive products.

Automotive Plastics Circularity Study

Guidance document to support programs for managing plastic packaging in the automotive supply chain.

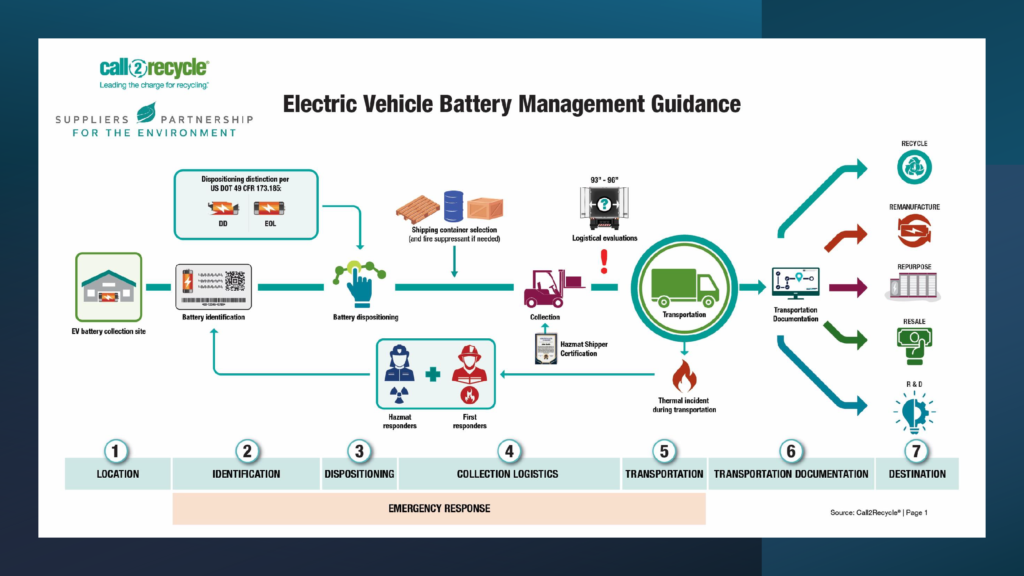

EV Battery Management Infographics

Infographics to visually inform battery holders of good practices to consider in preparing EV batteries for transportation.

Renewable Content Guidance

Industry-supported definition and straightforward approach for measuring renewable content of automotive products.

Recent News

Member Quotes

“Our group’s goal is to investigate and educate the industry on best practices for minimizing material waste in our closed-loop packaging system. We aim to increase the likelihood of diverting packaging from landfills or incineration. This forum brings together experts from across the packaging supply chain to collaborate towards a common objective: achieving packaging circularity.” – Bridget Grewal, Director Packaging CI, Magna International

“We recognize that companies handling EV batteries after they are removed from vehicles might lack essential information and training to ensure safe handling. Similarly, individuals may unknowingly take risks in their sincere efforts to act responsibly. This SP guidance document serves to bridge this information gap in a rapidly evolving industry, where real-life case studies and best practices are limited.” — Jeff Haltrecht, Executive, Call2Recycle

“Toyota is working to reduce the use of packaging and wrapping materials in our operations as we work toward our long-term goal to support a recycling-based society, and we expect our suppliers to undertake similar activities. Through this collaborative project, we are working to provide tools and resources to help the industry in its drive to minimize automotive packaging waste and continually improve sustainability. We believe that by working together with our suppliers and industry colleagues through organizations like SP, we can collectively scale up our positive impacts and make a significant difference for the environment.” — Matt Marshall, Supply Chain Sustainability, Toyota Motor North America.

“As we continue forward in our aspiration to maximize use of sustainable content in vehicles, we decided to pull together a team of automakers and suppliers with the objective to develop straightforward common definitions of key terms related to the topic of sustainable materials to minimize duplication of effort and promote consistent approaches in communications with suppliers, sustainability reporting and measuring industry progress.” — Sustainability Mission Leader, General Motors.